Ductile Iron ASTM A395 Grade 60-40-18 and Grade 65-45-15

on December 10, 2024

ASTM A395 is a nodular iron with a mostly ferritic microstructure and mechanical properties comparable to low alloy steels.

These grades are specifically for pressure-retaining castings that are used at elevated temperatures. Both grades are suitable for temperatures up to 450°F (232°C). For temperatures above 450°F (232°C), and as high as 650°F (343°C), only grade 60-40-18 is applicable.

Note: When the above elevated temperatures are not a concern, please see ASTM A536.

Only the chemistry of carbon (minimum), silicon (maximum), and phosphorus (0.08% maximum) is specified in the ASTM A395 standard. Other elemental values listed in this spec would be typical percentages.

Hardness is specified in this standard and can be seen in the table below.

Composition

| C | Mn | Si | Cr | Ni | Cu | Mg | |

|---|---|---|---|---|---|---|---|

| Min% | 3.00 | 2.00 | 0.025 | ||||

| Max% | 3.80 | 0.30 | 2.50 | 0.08 | 0.2 | 0.2 | 0.055 |

Physical and Mechanical Properties

| Property | Grade 60-40-18 | Grade 65-45-15 |

|---|---|---|

| Ultimate Tensile Strength (psi) | 60,000 | 65,000 |

| Yield Strength (psi) | 40,000 | 45,000 |

| % Elongation (min) | 18% | 15% |

| Hardness (HB, 3000 kgf Load) | 143 - 187 | 156 - 201 |

| Density lb/in³ (g/cm³) | 0.256 (7.1) | 0.256 (7.1) |

| Thermal Conductivity Btu/hr·ft·F (W/m·K) | 250 (36) | 250 (36) |

| Specific Heat at 70°F Btu/lb·F (J/Kg·K) | 0.110 (461) | 0.110 (461) |

| Coefficient of Thermal Expansion ε/F (ε/C) × 10⁶ average between 68-212°F |

6.4 (11.5) | 6.4 (11.5) |

| Melting Temperature | 2100°F | 2100°F |

| Compressive Strength psi (MPa) | 429,000 (2960) | 429,000 (2960) |

Heat Treatment

For the 60-40-18 grade, castings will almost always be heat treated to produce a ferritic microstructure. If the buyer agrees, and the tensile properties and hardness properties are met, heat treatment can be avoided.

Some foundries have the expertise to produce the 60-40-18 grade as-cast. By using specific charge materials and chemistry controls, material properties are achieved without the ferritizing heat treat process. A foundry with full heat treatment capabilities, however, will heat treat this alloy if/when required.

The foundry should do a stress relief / temper on ductile iron parts. This imparts a uniformity to the castings that is appreciated by machine shops during their operations.

Microstructure

For the 60-40-18 grade, the microstructure will be essentially ferritic and contain no massive carbides. It will also have a minimum of 90% type I and type II graphite.

The 65-45-15 grade will have the same graphite content and no massive carbides. Castings will, however, be 45% pearlitic (maximum) in their critical areas, which are identified by the buyer.

Pressure Testing

The buyer and the foundry need to work together at the design stage when pressure testing is required. The buyer may have to work to an ANSI or ASME code (or similar), and needs to ensure that the foundry is aware of this. In almost all cases, the casting will need to be machined before pressure testing commences. This will allow for plates or covers to be secured over openings so that the casting holds water/fluid.

Applications

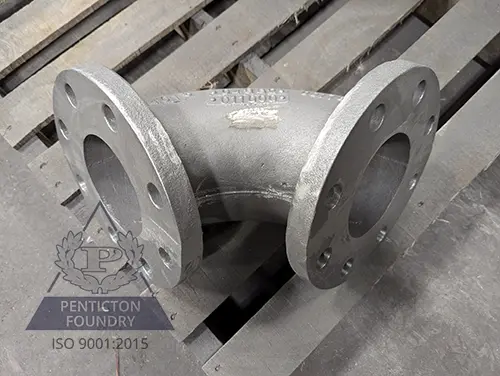

- Valves

- Flanges

- Pipe Fittings

- Pumps other piping component

Read: For more information on ductile iron ASTM A536 check out our ductile iron webpage.

Check out our Gallery to see some of our products