Where Innovation Lives

The Penticton Foundry’s blog offers product updates, client success stories, news and tips. It’s a place where research and innovation come together to keep our customers informed.

The Penticton Foundry’s blog offers product updates, client success stories, news and tips. It’s a place where research and innovation come together to keep our customers informed.

This ASTM A436 Type 1 datasheet offers information on material advantages, physical and mechanical properties, as well as design benefits.

A datasheet on ASTM A395 60-40-18 and ASTM A395 65-45-12. Information includes physical/mechanical properties, composition notes and applications.

How to ensure a successful collaboration between the customer, foundry and engineering firm in the casting design development process. Learn more here.

Penticton Foundry is committed to being a model for sustainability, while still meeting the needs of our clients and community. Read our blog to find out more.

High chrome white iron chute liners outlast AR 400 steel plate by 6x in a Yukon mine. Read the success story to find out more.

This blog explores why people are changing from Ni-Hard to high chrome white iron for abrasion resistant applications. Learn more today.

This data sheet focuses on ASTM A897 Grade 3 175 – 125 – 04 austempered ductile iron. It offers notes on composition, physical/mechanical properties and applications.

Some tips to assist engineers in selecting an alloy or material for an application. Read our blog for more information.

A list of different mill liners and the best alloys to maximize performance. Read our article to learn more.

How to select the best alloy for the challenges associated with flue gas desulfurization. Read this article and learn more.

In spite of the pandemic, Penticton Foundry has achieved several key milestones in the last 3 years leading to success throughout BC and North America.

To maximize the performance of your ductile iron castings it is important to ensure that rapid cross-sectional changes are avoided. Read more here.

Using chrome white iron in the potash mining industry can address wear challenges, leading to increased uptime. Read this blog to find out more.

Mitigate the challenges of the recent supply chain crisis by re-shoring your castings. A guide for a smooth transition. Read this blog for more information.

A chrome white iron liner package outperformed the former CCO solution by 5 years. Read our blog to learn more.

ASTM A319, is a heat resistant gray iron which has high temperature fatigue strength. Read our data sheet to find out more.

Consistent wall thickness is critical in ensuring the performance of chrome white iron castings. Read this blog to find out more.

Wind power castings, made from ductile iron, are a key component of wind turbines.

This gray iron data sheet focuses on A48 Class 40. Notes on physical and mechanical properties, as well as potential applications are included.

This data sheet focuses on gray iron ASTM A48 Class 20. It contains notes on composition, physical and mechanical properties, as well as potential applications.

There are some specific challenges in the hydraulic fracturing industry that chrome white iron, ASTM A532, can address. Read our blog to find out more.

Using chrome white iron, ASTM A532, in the mining industry is a smart choice for solving wear challenges. Read our blog to learn more.

This data sheet focuses on ASTM A536 120 – 90 – 02 ductile iron. It offers notes on composition, applications, and physical and mechanical properties.

This data sheet focuses on ASTM A536 100–70–03 ductile iron, and offers notes on heat treatment, composition, physical and mechanical properties.

Chrome white iron and ceramic have key differences when it comes to abrasion resistance, ease of machining and cost of purchase. Read our blog to find out more.

Penticton Foundry, in partnership with the National Research Council, offers a new wear sensor technology that’s a game changer. Read our blog to find out more.

A combination of chrome white iron, ASTM A532, and steel in piping applications can be a good idea. It increases wear life and helps meet piping codes

A mine in British Columbia got 7 times the wear life by replacing their rubber-lined discharge nozzle with chrome white iron. Read this success story today.

What is the best chrome white iron, ASTM A532 alloy, for preventing corrosion? If you have a challenge because of abrasive wear, read this blog.

One key benefit of iron production is that a foundry can melt down and reuse metal. Not only does this offer sustainability benefits, but significant cost savings.

This ASTM A536 data sheet focuses on low temperature, impact resistant ductile iron. It includes microstructure, mechanical property and application notes.

Wye laterals are used in a wide range of industries including the oil sands, mining, chemical processing, and waste management to transport liquids and slurries. Due to their caustic and/or abrasive composition, these materials can create substantial wear on parts, necessitating frequent replacement. The costs of replacement in both materials and downtime can be high.

Conventional ductile iron contains a mix of pearlite and ferrite in the matrix surrounding the nodules. This mix, depending on different cooling rates throughout the casting, can cause large ranges in mechanical properties like hardness.

The 30% Cr alloy is designed for use in applications like flue-gas desulfurization (FGD). The higher Cr content makes this alloy especially useful when conditions of severe acid corrosion exist and when high Cl ion concentrations are present.

Because of its unique microstructure, chrome white iron offers superior abrasion resistance over other alloys, including steel. But ASTM A532 also confers specific recycling, reusing and repairing advantages over rubber and ceramic products, resulting in a lower environmental impact and significant cost savings.

Located in British Columbia, Canada, Penticton Foundry has become known for its game changing innovations in the use of ASTM A532, chrome white iron. Achieving this level of success requires constant dedication to furthering our expertise. It means investing in our people, processes and equipment, and ensuring that our customers’ expectations are exceeded every day.

A mine in British Columbia, Canada was looking for a material to replace manganese steel in their gyratory crusher liners. The mine required good wear properties, coupled with the ability to absorb great impact at low temperature.

ASTM A48 Class 30 (Related Standards – DIN GG20, BS 1452 Grade 220) is a gray cast iron. Gray iron consists of graphite flakes in a metallic matrix. When fractured, it is grayish in colour – hence the name (specifically, a fracture will follow along the graphite flakes which are gray). The low cost of production and attractive properties make gray iron one of the most commonly used ferrous alloys.

Sometimes, you get a success story that helps illustrate why many companies are shifting to chrome white iron in abrasion applications. But what are the challenges that are specific to the Oil Sands, and what is it about chrome white iron that makes it so effective there?

When materials are exposed to an abrasive environment, the media flow rubs against them, often leading to material loss over time. This can be mitigated by carefully choosing the correct material for abrasive areas.

From “chrome white iron is brittle” to “you can’t machine ASTM A532,” you’ll often hear myths when it comes to chrome white iron. But the reality is that ASTM A532 outperforms steel, AR plate and weld overlay in many applications requiring abrasion resistance.

When designing with ductile iron as an engineer you may notice that almost all ductile iron standards don’t specify a chemistry requirement. This is because the microstructure and mechanical properties can be achieved in different ways.

Why Use Chrome White Iron ASTM A532, or high chrome white iron, has superior abrasion resistance. It is particularly effective in machinery or equipment that experiences grinding, gouging abrasion or crushing.

ASTM A536 60-40-18 is a nodular Iron with a mostly ferritic microstructure and mechanical properties comparable to low alloy steels. Ductile iron 60-40-18 is one grade in a family of many. Chemistry requirements are not specified in the ASTM A536 standard. Chemistry and hardness listed in this spec would be typical for a Grade 60-40-18.

High chrome white iron, or ASTM A532 has a number of myths attached to it, the least of which is that it is brittle. The superior wear resistance of chrome white iron to steel, or AR 400 plate, however, makes it a natural choice for applications requiring abrasion resistance. A recent success story in the Oil Sands illustrates this.

In any business, relationships are key to success. The manufacturing industry is no different. This infographic offers tips to building a collaborative relationship with your foundry of choice. Doing so will help ensure that the casting process runs smoothly and that the part you receive meets your expectations.

Ni-hard is also called ASTM A532 Class I Type A. This blog explores the differences between Ni-hard and ASTM A532 Class II and III in an easy-to-read chart form. Microstructure differences will be examined and application suggestions made.

There are a number of myths about chrome white iron. One of the most common is that high chrome white iron is too brittle for many applications.

Austenitic ductile iron, also known as Ni-Resist, creates a stronger casting than ductile iron. Read our ASTM A439 Grade D2 58-30-8 data sheet.

Penticton Foundry solved a manufacturer’s delivery/supply chain issues. Read about how our patternless 3-D printed mould helped our client.

Avoid these design mistakes when designing ductile iron castings. Maximize your ASTM A536 casting performance.

ASTM A532 high chrome white iron significantly outlasts AR plate. Read our apron feed liner success story.

Avoid these mistakes when designing chrome white iron castings. Maximize your ASTM A532 casting performance with these tips. Read our blog today.

Data sheet on austempered ductile iron ASTM A897 Grade 1 130–90–99. Get the facts on ADI today.

There are a number of reasons why you cannot weld chrome white iron. This blog offers some viable alternatives to welding ASTM A532.

The casting process offers a number of advantages over the custom metal fabrication process, including cost savings and better lead times.

High chrome white iron, ASTM A532, offers superior abrasion resistance. Read about how high chrome white iron outlasted steel by a factor of 6 times.

High chrome white iron ASTM A532 outperforms AR 400 for many applications. Read our blog to get the microstructure and macrostructure notes today.

Understanding the properties of high chrome white iron and its applications. Read our blog to find out more.

Understanding the properties of ductile iron and its applications. Read our blog today to find out more.

This chart, by Penticton Foundry, offers a comparison of two high chrome white irons, ASTM A532 Class I Type A and ASTM A532 Class II Type D.

Data sheet for ductile iron ASTM A536 grade 80 – 55 – 06. Related standards – SAE J434C D5506, ISO 1083 500-7. Read our spec sheet for composition, and other details.

Chrome white iron liner created for a primary separation cell lower sump cone outlasts CCO by a factor of 20 times. Read our case study.

ASTM A532 Class I Type A or Ni-Hard 1 is an abrasion resistant high chrome white iron good for low or medium dynamic stresses. Read our data sheet today.

Ductile iron has a number of machining advantages when compared to steel. Read our blog to learn about how ductile iron can outperform steel.

Data sheet for ASTM A532 Class II Type D high chrome white iron. Read about the toughness and abrasion resistance of this alloy.

Diamond 25 is a high chrome white iron. Read our data sheet on this ASTM A532 Class III Type A alloy.

ASTM A532 Class II Type B high chrome white iron is used in operating environments where abrasion and impact are the wear mechanisms.

ASTM A532 Class III Type A data sheet on Tough 25 which is a high chrome white iron. Good for thicker section castings.

A local mine just witnessed a dramatic visual testimony as to the superior wear performance of chrome white iron versus AR400.

ASTM A536 65-45-12 is a nodular Iron with a ferritic and pearlitic microstructure and mechanical properties comparable to low alloy steels.

Pliant25 is a unique high chrome white iron that has been perfected by Penticton Foundry.

The 25% Cr alloy is the most common high chrome white iron poured at Penticton Foundry.

There are a number of myths about high chrome white iron. Myths include the idea that high chrome white iron is not impact resistant, or that it can’t be machined.

Penticton Foundry is pleased to announce that we have joined MARIOS (Materials and Reliability in Oil Sands).

A comparison of ductile iron vs steel across a range of properties.

A collection of Penticton Foundry’s chrome white iron wear liners. Our proprietary process lets us machine chrome white iron. Read on to find out more.

Penticton Foundry has created an alloy comparison chart that includes chrome white iron, ductile iron, ADI and gray iron.

A multinational oil and gas company approached Penticton Foundry to solve a wear problem with their 90° CCO spool which needed to be removed from service every 12 weeks (2000 hours) and weld repaired.

What does tensile data say about the strength and ductility of ductile iron as opposed to cast steels?

An OEM crusher came with a steel lock nut. Unfortunately the lock nut had accelerated wear issues and was prohibitively expensive to replace.

A local mine in British Columbia, Canada changed the opening of their discharge screens on their SAG mills.

A high chrome white iron drain spool liner was engineered to replace a CCO drain spool, increasing wear life by 5 times. Read our blog to find out more.

Ductile iron and gray iron are two different kinds of cast iron with specific applications. Read this post today to understand the differences.

A customer had increased the size and volume of the media flowing in the fully autogenous milling circuit. This created some very specific challenges, particularly because the trunnion discharge liner, which had been made of rubber, was now lasting 6 weeks rather than the 1 ½ years it had previously. The customer approached us looking [more]

One of the most common myths about high chrome white iron is that it cannot be machined.

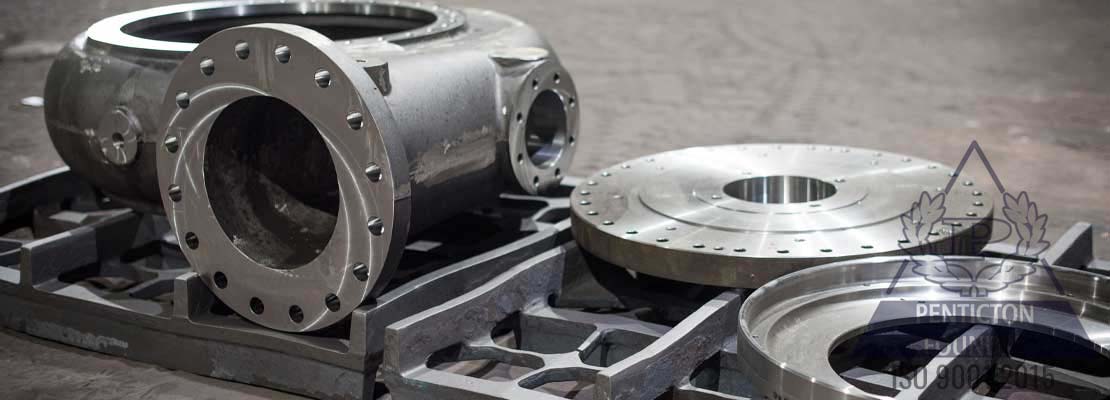

Some of the products we make at Penticton Foundry.

The Wyes and Laterals were recently inspected after twelve months operation.

Take a quick tour of Penticton Foundry with our video.

In a continuing effort to maintain and improve upon our foundry process, Penticton Foundry has made many changes over the years.

This is the 7000 lb solid chrome elbow that we produced for a mine in the Alberta Oil Sands being poured.

We have standard patterns available for wear liners.

A major Oil Sands facility replaced CCO 28″wye and lateral piping assemblies with bi metallic piping from Penticton Foundry.

Penticton Foundry recently shipped a 60 degree solid chrome elbow to a mine in the Alberta Oil Sands.

Penticton Foundry supplies ASTM A532 chrome iron fracking components that outlast fabricated components

An oil sands customer had a problem with extreme high wear on pump spools in the hydrotransport line for oil sands.

An oil sand customer from Ft McMurray had a Cyclofeeder liner that required new wear liners.

One of our oil service companies used our Pliant 25 alloy to improve the wear life of their sand slingers.

CADI feed chute liners on a usage trial at a large Canadian copper mine.

Austempered Ductile Iron (ADI) gear segments used in the mining industry.

Balanced Machined Impellers at >600BHN in ASTM A532 CLIII Type A.

A 5800 pound ASTM A532 CLIII Type A >650BHN fully machined casting made for a mine here in British Columbia.

One customer’s success story. 17 times savings based on acquisition cast, running costs and expected life span!